This is a brief history of Iraq’s attempt to build a nuclear weapon. The emphasis is on Iraq’s technical achievements rather than its motives, and the history relies primarily on the findings of U.N. inspection teams.

Iraq faced the same two challenges that every other country trying to develop a nuclear weapon has faced. First came the need to produce a critical mass of “fissile material” – uranium 235 or plutonium – the heavy metals needed to fuel a first-generation fission bomb. The second challenge was to produce a device that could cause the uranium or plutonium to explode in a nuclear chain reaction. This second process is called weaponization. Iraq attacked both challenges simultaneously.

Iraq spread the work among four major groups, all of which operated within the Iraqi Atomic Energy Commission, and more specifically within the Commission’s Department of Studies and Development (also known as Department 3000). Group I was responsible for producing uranium 235 by using diffusion barriers and centrifuges. Group II tried to do the same by using chemical and electromagnetic methods. Group III was responsible for computer modeling, and Group IV performed “special tasks,” another term for weaponization. The program carried the code name Petrochemical 3 (PC-3).

I. Seeking Nuclear Fuel

Producing the fuel has always been the greatest challenge in nuclear bomb making. The difficulty of producing uranium 235 is that natural uranium contains only a very tiny amount (.7%) of this isotope. In order to fuel a bomb, the U-235 must be separated from the more abundant U-238 isotope in a process called enrichment. But because these two uranium isotopes are almost identical chemically, they cannot be readily separated by using a simple chemical reaction. They must be separated by exploiting the slight difference in their weights. Plutonium, on the other hand, is not found in nature in significant quantities, so it must be manufactured in a nuclear reactor.

Electromagnetic Isotope Separation (EMIS)

Iraq’s main effort to produce U-235 was by the electromagnetic process (called EMIS). In this process, uranium atoms are ionized (given an electrical charge) then sent in a stream past powerful magnets. The heavier U-238 atoms are affected differently than the lighter U-235 atoms by the magnetic field, so the isotopes separate and can be captured by collectors. The separation process is repeated until a high concentration of U-235 is achieved. Iraq’s design called for 93% enriched uranium, which required multiple stages of separation.

Iraq began this effort at the Tuwaitha site in 1982 after Israel bombed Iraq’s Osirak reactor. The first separator unit (with a 400mm radius of beam curvature) was built to test Iraq’s concept for the unit’s insulator and liner. The 400mm unit was followed by 500mm and 1000mm units, used to test larger ion sources, multiple ion sources and a hexagonal liner design, as well as concepts for the control system and collectors. Next, components of a 1200mm system were designed for Tarmiya, and the magnet for a 600mm machine at Tarmiya was actually built. A double ion source and collector system for the 600mm unit was also designed. At the time of the Gulf war, eight 1200mm units were in limited operation at Tarmiya, and preparations had begun for a second group of seventeen 1200mm separators. According to Iraq’s declarations to U.N. inspectors, it managed to produce 640 grams of enriched uranium with an average enrichment of 7.2% at Tuwaitha and some 685 grams at an average enrichment of 3% at Al Tarmiya.

Centrifuges

Iraq also attempted to enrich uranium with high-speed centrifuges. This effort had lower priority than the EMIS program. Centrifuge separation works by passing uranium molecules in gaseous form (UF6) through high-speed rotational machines called centrifuges. The different weights of the uranium isotopes cause them to separate, with the heavier U-238 being thrown to the outside of the centrifuge and the lighter U-235 staying nearer the inside. As with other enrichment techniques, centrifuges require several repetitions with the enriched product to reach a high enough concentration to serve as nuclear fuel.

Iraq planned an ambitious research and development effort for its centrifuges. From mid 1987 to late 1989, Iraqi scientists conducted trials on a “model 1” centrifuge. It was an early Beams-type gas centrifuge using oil bearings, which ran into difficulties with vibration. It also consumed large amounts of power. Then from mid-1988 to mid-1991, Iraq ran trials on a “model 2” centrifuge. This was a Zippe-type centrifuge using magnetic bearings and a maraging steel rotor spinning at sub-critical speeds, for which the design drawings were provided by an ex-employee of the German firm MAN Technologie AG. Also during this period, another German national, Karl-Heinz Schaab, provided the design of a sub-critical centrifuge featuring a carbon fiber composite rotor. Schaab also furnished a quantity of sample rotors, which Iraq exploited successfully by achieving an output of 1.9 kg SW/year in 1990. Iraq also obtained 25 pieces of maraging steel from an unidentified source, 19 of which it machined into centrifuge preforms at Nasser Engineering Establishment while six more were machined by an unidentified foreign company.

Iraq planned to construct (with the help of foreign companies) a centrifuge plant at Al Furat between late 1989 and mid-1991. Trial operation was scheduled for the second half of 1991. Iraq also planned to design and construct a 100-centrifuge cascade at Al Furat between 1991 and mid-1993, when Iraq hoped to begin active operation. In addition, Iraq planned to design and construct a 500-centrifuge cascade from mid 1992 to mid-1995. The centrifuges and pipework for this latter cascade would be installed in 1995, and operation would start in early 1996.

The fourth International Atomic Energy Agency inspection team estimated that 1,600 to 2,000 Iraqi-designed maraging steel centrifuges in cascade could produce about 25 kg/yr of HEU. The team also found that Iraqi plans for the program “would most probably have been achieved once the capability to flow-turn and weld maraging steel had been acquired.” This quantity of HEU would have been enough for about 1.5 bombs per year.

Laser Isotopic Separation (LIS)

Because isotopes of different masses absorb different wavelengths of light, uranium isotopes can be separated by lasers precisely tuned to excite or ionize only the U-235 atoms in a stream of atomic vapor (atomic vapor laser isotope separation, or AVLIS). The U-235 is then separated out using a chemical reaction or magnetic forces that attract the excited atoms and leave behind the neutral ones.

In May 1994 the IAEA received information indicating that Iraq had pursued laser uranium enrichment through both molecular and atomic vapor isotope separation. But the IAEA did not believe Iraq had made substantial progress in either. The IAEA had no evidence that these efforts achieved any isotopic separation, or that Iraq had developed even the most rudimentary capabilities. In September 1994, however, Iraq admitted that an exploratory laser program had indeed been established in 1981 and was assigned to the laser group within the Physics Department of the Iraqi Atomic Energy Commission. Iraq said that this program continued, without success, until 1987, when it was relegated to a “watching brief.” IAEA-26 found Iraq’s explanation of its laser activities plausible, but was surprised that Iraq said it had not undertaken the relatively simple step of vaporizing uranium metal. After August 1995, the IAEA learned that Iraq had in fact made two attempts to build a suitable vacuum chamber for AVLIS experiments, the second of which succeeded. Moreover, the chamber was equipped with an electron beam gun for vaporizing uranium metal. Iraq’s AVLIS experiments in 1986 and 1989 were inconclusive, however, and Iraq claimed that further work was abandoned due to these failures and the low priority given to the laser program.

Chemical and Ion-Exchange Separation

Although U-235 and U-238 are nearly identical in chemical composition, they vary enough to have different chemical reaction rates. Thus, chemical reactions which take advantage of this fact can be used to separate the isotopes.

Iraq made some progress in chemical (solvent extraction) and ion-exchange methods of uranium enrichment before the Gulf war. The effort was centered at the Nuclear Research Center, Tuwaitha, except for the production of tri-butyl phosphate which, together with some theoretical work on crown ethers, had been done at the Muthanna State Establishment. The reason for chemical enrichment was to provide feedstock for the EMIS separators, so they could begin with low enriched uranium instead of natural uranium, thereby boosting efficiency. Iraqi research in solvent extraction appears to have been limited to laboratory-scale, but Iraqi scientists expressed confidence that they could have overcome any practical problems during scaling-up, and had begun buying components for a pilot plant to produce four metric tons per year of 1 to 1.2 % enriched uranium. Iraq stated that ion exchange enrichment was also promising, but that experience with it was limited. Its laboratory scale experiments, using indigenously produced ion exchange resins, produced only modest results. A project for a pilot plant to produce four metric tons per year of up to 3% enriched uranium had not gone beyond a preliminary assessment of the equipment and material needed. According to Iraq, the most promising project, though still at the conceptual design stage in late 1990, combined both enrichment methods in a hybrid process having a solvent extraction first stage and an ion exchange output stage, in order to produce up to 5 metric tons per year of 4 to 8% enriched uranium.

Gaseous Diffusion

In gaseous diffusion enrichment, uranium is converted into gaseous form (UF6) and then sent through a porous barrier. Lighter, faster U-235 molecules diffuse through the tiny holes in the barrier faster than the U-238 molecules, and thus separation occurs. Again, multiple stages in a cascade are required to produce weapon-grade material.

Group I of PC-3 apparently began its effort to produce diffusion barriers and compressors at Tuwaitha. Iraq confirmed that this work continued after Group I was relocated at the Engineering Design Center (Rashdiya) and that some significant achievements had been attained in the development of anodized aluminum barriers. Iraqi scientists had demonstrated the corrosion resistance of barrier material to UF6 and had achieved measurable uranium isotopic separation. However, according to an Iraqi scientist, this activity, which was carried out in 1989, had not progressed beyond the qualification of a single barrier. In parallel to the barrier studies, Group I attempted to reverse-engineer compressors, in cooperation with Iraq’s Specialized Institute for Engineering Industries, but Iraq claimed that this attempt was not successful. According to Iraq, all activities related to gaseous diffusion ended in 1989 and priority was given instead to gas centrifuge enrichment. According to the former director of Iraq’s nuclear weapon program, Khidir Hamza, however, the Iraqis perfected the diffusion barrier in 1993, under the noses of the inspectors. Dr. Hamza believes that diffusion is the most likely path a reconstituted Iraqi nuclear program would take in order to enrich uranium for its bombs.

Diversion of Reactor Fuel

After its invasion of Kuwait in 1990, Iraq intended to illegally divert to bomb-making a quantity of highly enriched uranium that was being inspected by the IAEA. The HEU was contained in the fuel of Iraq’s two research reactors at Tuwaitha. Iraq had at its disposal some 41 kg of U-235 in its supply of research reactor fuel from Russia and France. The effort to divert that fuel, known as Project 601, started shortly after Iraq’s invasion of Kuwait in August 1990. By December 1990, a chemical processing plant had been installed in the LAMA building at Tuwaitha which Iraq hoped would make available 26 kg of HEU within 2-3 months. The building was severely damaged, however, in the Gulf war, and plans were made to move a scaled-down project to Tarmiya. The IAEA’s decision to remove the reactor fuel, starting in November 1991, meant the end of the crash program.

Plutonium Separation

Because the plutonium isotope 239, which is used to fuel fission bombs, exists naturally only in trace amounts, it is necessary to manufacture plutonium in a nuclear reactor. This is done by bombarding U-238 with slow neutrons. When the U-238 captures a neutron, the U-239 isotope is produced, which decays into plutonium 239.

Iraq used its Russian-supplied IRT-5000 research reactor to irradiate (noncontinuously – to avoid detection during IAEA inspections) three U-238 fuel elements manufactured from December 1988 to February 1989 at Iraq’s Experimental Fuel Fabrication Research Laboratory (known as ERFFL or EFFRL). Iraq also irradiated one element for 22 days between February and April 1989, and two additional elements for 50 days between September 1989 and January 1990.3

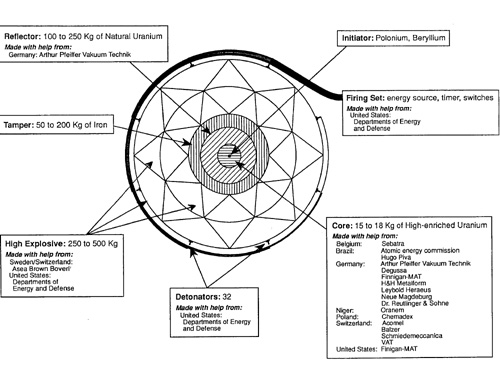

II. Weaponization

In 1995, Iraq admitted to the IAEA that it had considered several implosion-type bomb designs. Iraq claimed that it gave no serious consideration to the simpler, gun-type uranium bomb that the United States dropped on Hiroshima. Iraq ran the computer codes pertinent to these designs on a Japanese NEC 750 computer located at Tuwaitha, which was moved to the National Computer Center after the Gulf war. Iraq also experimented with high explosives to produce implosive shock waves and developed a 32-point electronic firing system using detonators developed at Al Qaqaa. The firing system was tested and gave satisfactory results. For research purposes, Iraq also used flash X-ray systems (180, 600 and 1200 kV), and two gas guns (light gas and high-explosive-driven gas). Iraq used fiber optics with fast response electronic equipment, and high speed electronic streak cameras – all to diagnose and perfect a workable bomb design.

Iraq also admitted studying several approaches to building a neutron initiator, which supplies the neutrons necessary to set off a nuclear chain reaction. Iraq produced and recovered tritium by irradiating lithium, and produced and recovered polonium by irradiating bismuth.

A special unit in Al Qaqaa was created to help Group Four develop and manufacture the high-explosive lenses and detonators needed for the implosion device. This group developed manufacturing processes such as rigid die-pressing of mixed explosives and plastic-bonded explosives, atmospheric and vacuum casting of melt-cast explosives, and casting of explosive/polymer composites. By the end of 1990, Iraq could perform computer numerical controlled (CNC) machining of high explosives.

The Al Qaqaa team was also responsible for developing and producing plane wave lenses During 1990, the team produced lenses with various diameters (up to 120 mm) and lengths. These lenses were tested or used as plane wave generators for shock-wave experiments. Iraq also started working on spherical lenses as early as 1988, and experimented with various kinds of explosives, including Baratol, PETN, COM-B, TNT, RDX and HMX. Iraq revealed to IAEA-4 that hundreds of tons of HMX had been imported, and that Iraq had gained “considerable experience in casting such material.” The HMX was used to make improved explosive lenses for the Iraqi bomb. The Al Qaqaa team also mastered the design of dedicated exploding bridge wire (EBW) detonators, after experimenting with several types. In fact, the U.S. Departments of Defense and Energy helped train three Iraqi scientists from Al Qaqaa at a quadrennial international detonation conference in Portland, Oregon, where nuclear weapon detonation technology and flyer plate technology were presented. The latter is used to control the force and shape of implosive shock waves.

UN inspectors learned that Iraq’s first bomb design, which weighed a ton and was a full meter in diameter, was replaced by a smaller, more efficient model. From discussions with the Iraqis, the inspectors deduced that the smaller design weighed only about 600 kilograms and measured only 600 to 650 millimeters in diameter. That made it small enough to fit on Iraq’s Scud-type missiles, which were never completely accounted for. Iraq mastered the key technique of creating an implosive shock wave, which squeezes a bomb’s nuclear material enough to trigger a chain reaction. The smaller Iraqi design also used a “flying tamper,” a refinement that “hammers” the nuclear material to squeeze it even harder, so that bombs can be made smaller without diminishing their explosive force. The inspectors determined that Iraq had managed to develop a successful bomb design and lacked only the fissile material to fuel it.